We provide custom metal fabrication and integration services to companies across the globe.

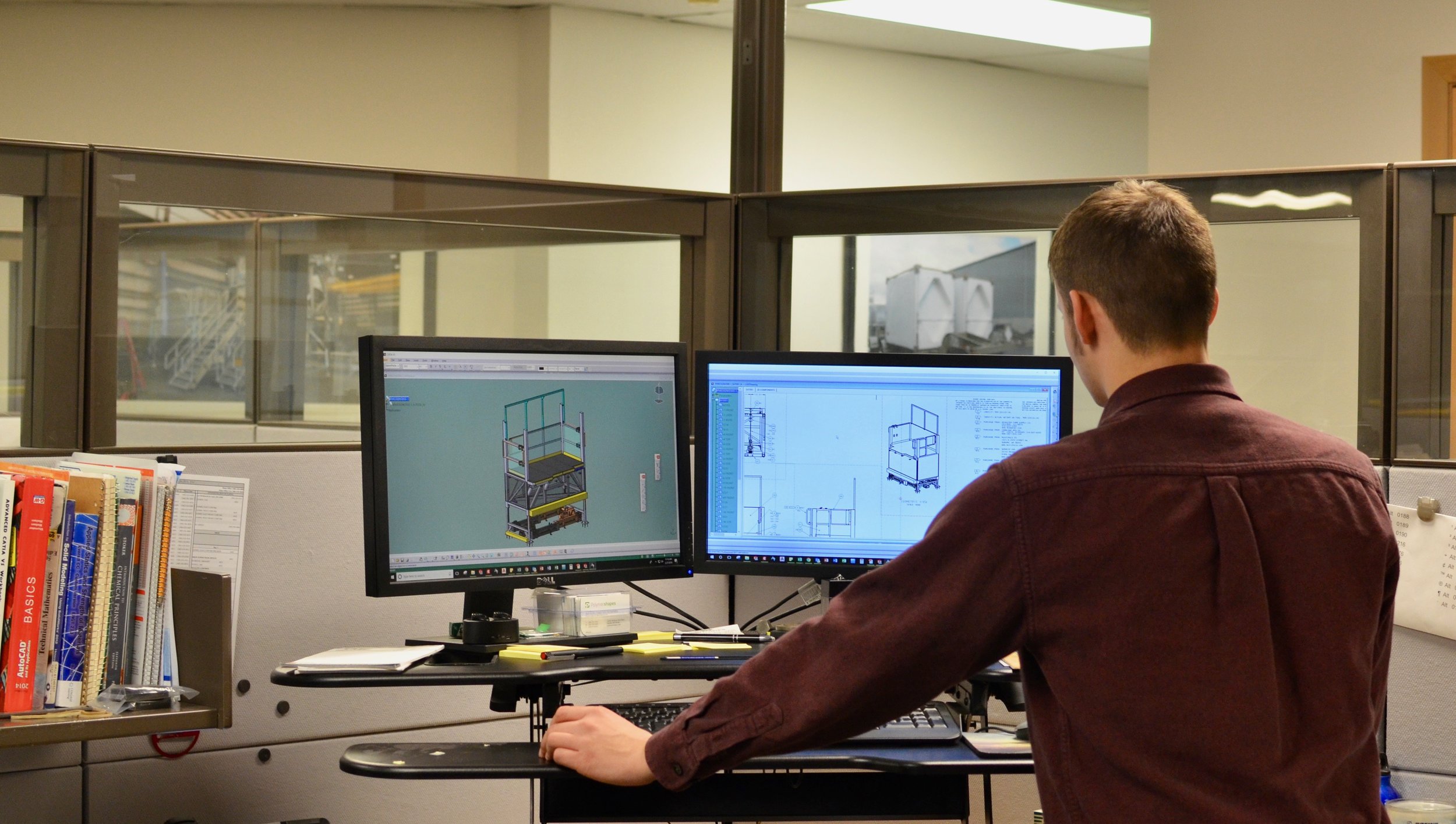

Beyond our skilled welding, we bring together components from various suppliers to assemble, test and deliver unified, turn-key products to our customers. Our ability to execute highly customized, large-scale projects in accordance with rigorous industry regulations sets us apart.

Capabilities

Structural Fabrication

Exotic Welding

Turning and Milling

Shearing and Forming

Material Finishing

Hydraulics and Pneumatics

Blasting, Painting, Coating and Metalizing

Testing and Inspection

Assembly and Integration

Specializations

Tooling

Composite Tooling

Canisters, Vessels and Tanks

Shipping Packages

Mechanical Handling Equipment

Ground Support Equipment

Structural Steel

Support Racks

Custom Skids and Modules

Welding Disciplines & Qualifiations

Flux Core Arc Welding (FCAW)

Gas Tungsten Arc Welding (GTAW)

Gas Metal Arc Welding (GMAW)

Shielded Manual Arc Welding (SMAW)

Submerged Arc Welding (SAW)

Stud Welding/Spot Welding

Semi-Automatic and Manual Processes

ASME Code IX, AWS D1.1,

AWS D1.2, & AWS D1.6

Facility Highlights

Turning Capacity: Up to 27” Diameter

Milling Capacity: 16’ x 7’ x 2’

Shearing Capacity: Up to 3/8” Thick

Rolling Capacity: Up to 2” x 10’

Indoor Lifting Capacity: Up to 70 tons, 30’ Hook Height

Pressing Capacity: 500 Tons – Up to 22’ in Length

Testing & Inspection

Three Boeing-delegated inspectors

AWS QC1 Certified Weld Inspectors

Mechanical and receiving inspectors

SNT-TC-1A Ultrasonic Testing Level II

SNT-TC-1A Visual Inspection Level II

SNT-TC-1A Liquid Penetrant Level III

SNT-TC-1A Magnetic Particle Level III

SNT-TC-1A Leak Testing Level II and III

Quality Assurance & Security

AS9100D

ISO 9001:2015

NQA-1

ASME Code IX

AISC BU, SPE-P1

ITAR compliant/registered

NIST SP 800-171